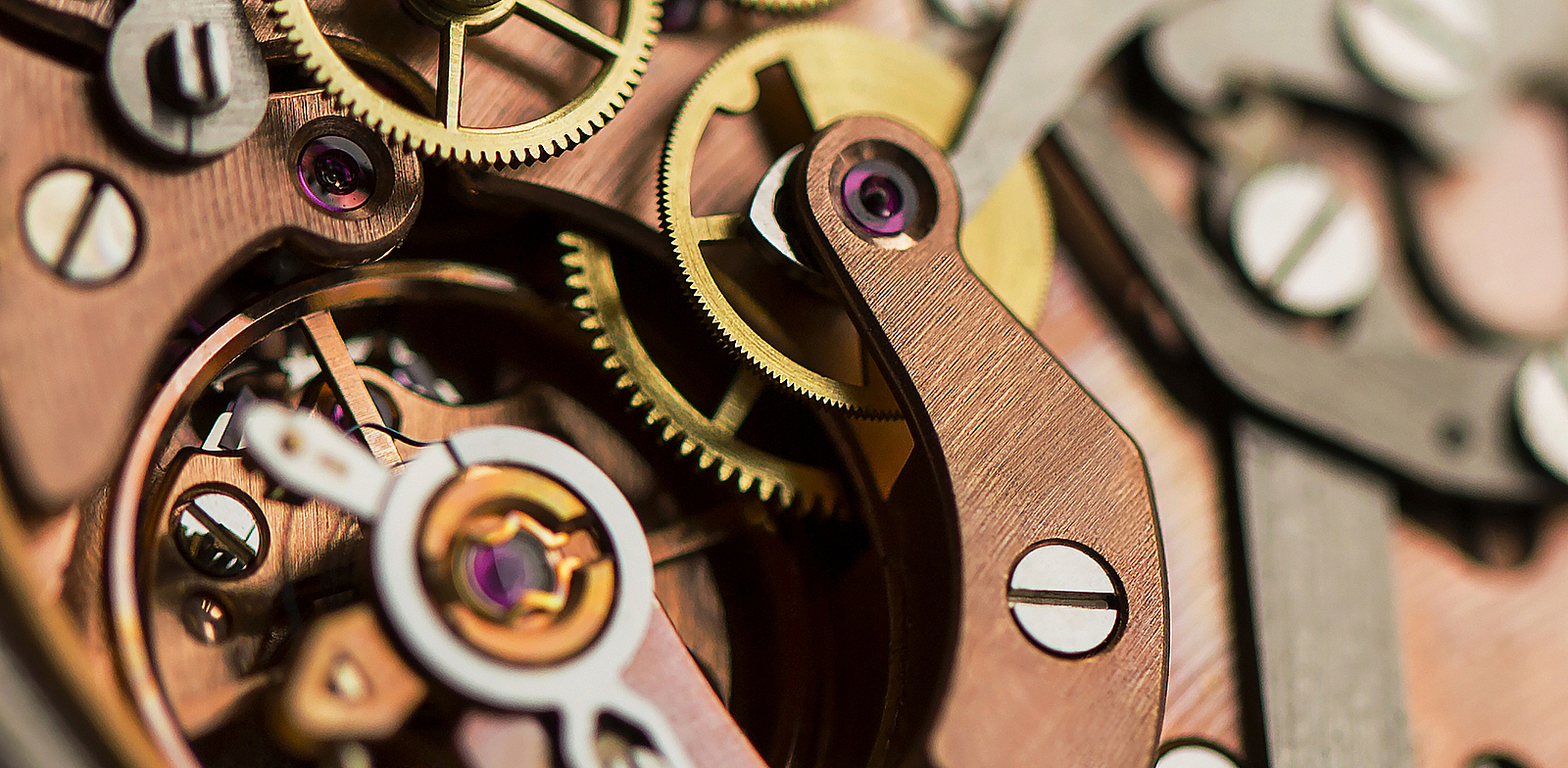

The Groupe Recomatic has been accompanying the watch making industry since 1952 in a great many finishing challenges

The quality objectives in the watch sector are unequalled. The expert eye of Quality specialists detect the tiniest imperfections on the surfaces of finely polished or satin-finish components. Our RECO and BULA machines meet the most stringent finishing requirements with all materials such as stainless steel, titanium, precious or semi-precious metals ceramic or sapphire.

Leader since 1952, the Groupe Recomatic is your partner of choice for finishing and embellishment specific to watch making, whether it's for moving parts, dials, crowns and push-buttons, strap components, sapphire faces, backs or case centres.

Perfect geometry with RECO machines

Homogeneous mirror-finish polishing with BULA machines

An experienced team to support you

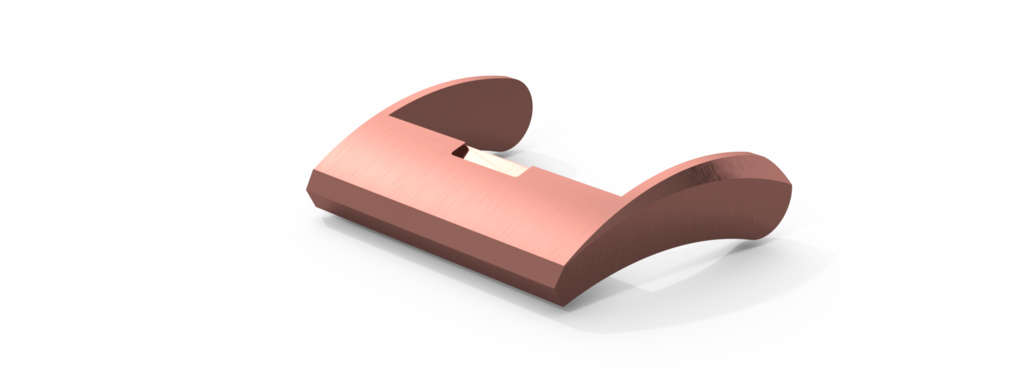

Applications

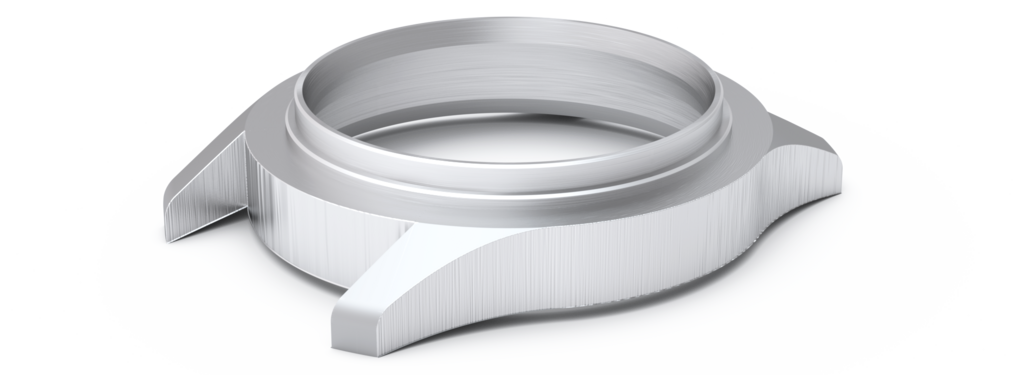

Grinding on RECO-CT501

Before grinding (blank part with burrs)

After grinding

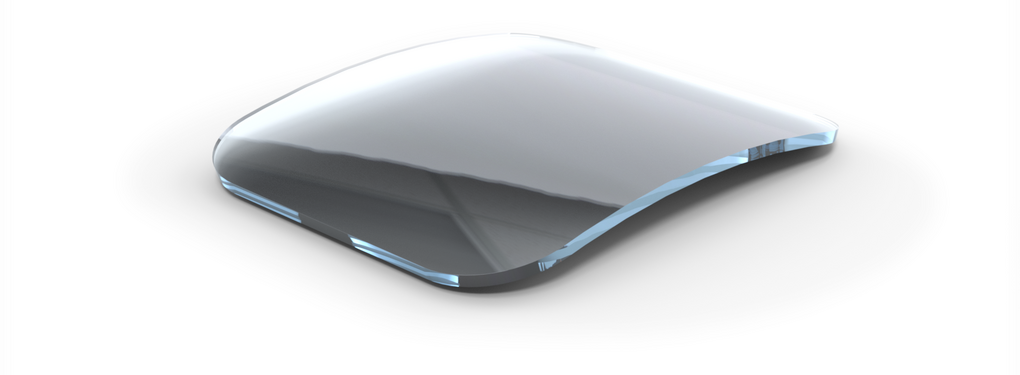

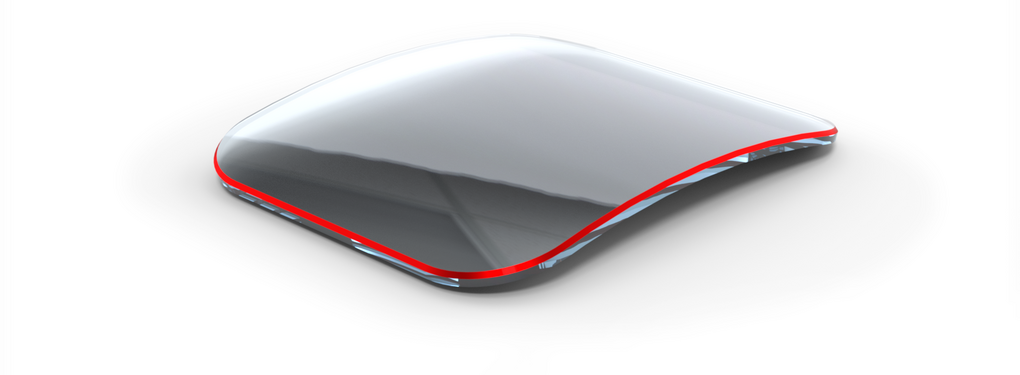

Polishing on BULA POLIGO B1 / B2 / B3

Before polishing

After polishing

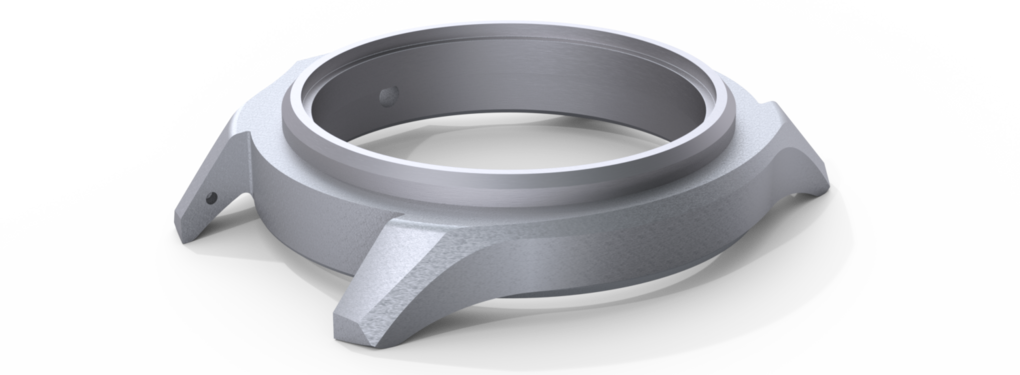

Ceramic grinding on RECO-CT501 or MR430

Blank part

Ground part

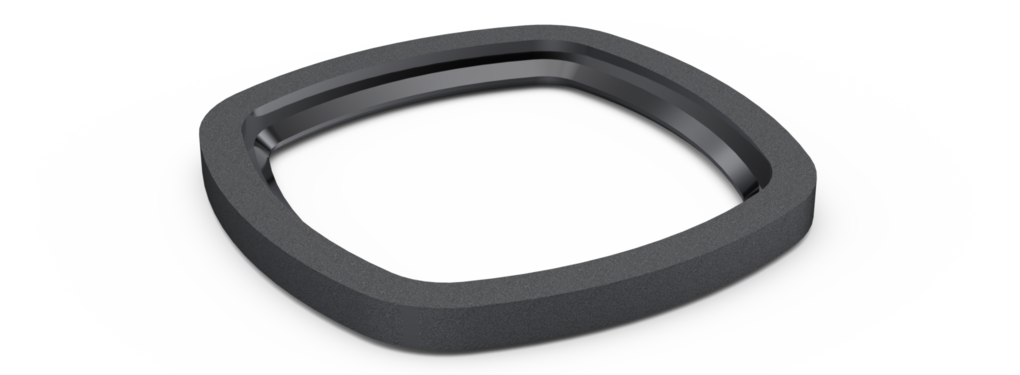

Bevelling on RECO-CT501 or MR430

Before bevelling

Bevelled zone

Polishing on BULA POLIGO B1 / B2 / B3

Before polishing

After polishing

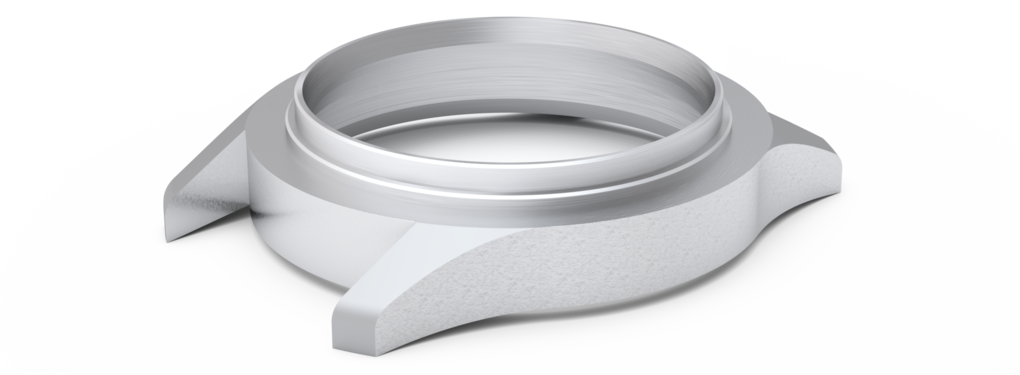

Satin finishing on RECO-CT501 or MS310

Before satin finishing

After satin finishing

Our showroom

In our showroom there is a team of multi-disciplinary specialists ready to develop with you the most avant-garde grinding, deburring, polishing, brightening and embellishing processes. Ever-ready to take up new challenges with you.

Les machines pour l'industrie horlogère

CT5

Ultra-compact, environmentally friendly CNC finishing centre

- Sturdy design

- Optimized chip removal

- 5 axis cinematics

CT501

Compact CNC finishing centre

- 6 digital axes 5 of which are simultaneous

- High rigidity enables hard materials to be machined

- Tool spindle 18'000 rpm

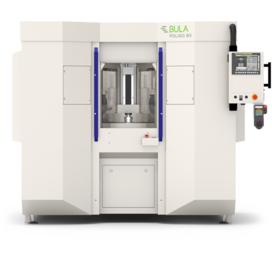

POLIGO B2

CNC Polishing, deburring and brushing machine

- 2 CNC units allowing simultaneous execution of different operations

- Machine configuration according to your requirements

- Precision, repeatability, productivity and user-friendliness

MR430

CNC grinding and lapping machine

- 5 digital axes 4 of which are simultaneous

- Fast operation, reducing cycle times

- High rigidity enables hard materials to be machined

BU200-UR

UR-compatible finishing equipment range

- Create your own robotized surface finishing cell

- Universal Robots-compatible range of finishing equipment

- Unequalled modularity, simplified integration, and intuitive control software

BP150

Polishing bench

- Choice of working position with electric height adjustment (optional electric feet)

- Quick access to the dust filter for easy maintenance (Standard size filters)

- Air suction with integrated frequency converter as standard

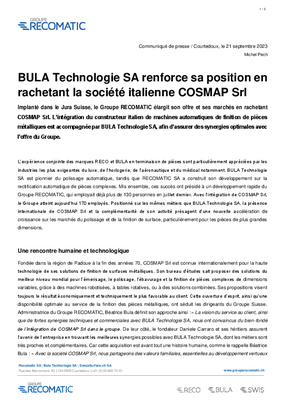

MS220

Circular satin-finishing machine

- 4 axis cinematics

- High performance machine

- Complete protection of the mechanical components (covers, bellows and over-pressurization)

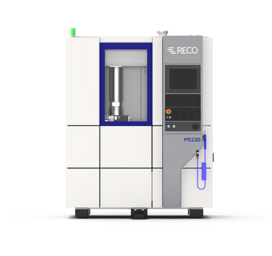

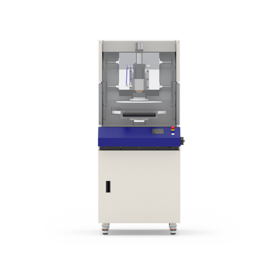

POLIGO B1

CNC Polishing, deburring and brushing machine

- 1 CNC work unit

- Machine configuration according to your requirements

- Precision, repeatability and user-friendliness

ML100

Manual lapping machine

- Highly modular thanks to the W20 interface and the design of the tooling support

- Machine offered with adjustable feet or on one of our range of BP workbenches

- Compatible with BU200 series disks and some accessories

MR401

CNC grinding machine

- 4 simultaneous digital axes

- Double tool spindle for machining between lugs and watch case sides simultaneously

- Spring bar hole drilling

POLIGO B3

CNC Polishing, deburring and brushing machine

- 3 to 5 CNC units for carrying out different operations simultaneously

- Machine configuration according to your requirements

- High rates can be achieved

MS300/310

CNC satin finishing machine

- 4 or 5 numerical axes according to model

- Device with 2 orientable abrasive belts

- Extremely compact volume and dimensions of the machine

BP300

Polishing bench

- Choice of working position with electric height adjustment (optional electric feet)

- Quick access to the dust filter for easy maintenance (Standard size filters)

- Optimisation of space thanks to perfect interlocking benches

MP304

Automatic polishing, deburring & brushing machine with rotating table

- Compact monobloc machine equipped with 4 work units

- Production can reach up to 1,800 workpieces/hour

- Programmable rotating table equipped with 12 or 18 workpiece holder spindles

microL

Smoothing and deburring machine

- Replaces tedious manual operation

- Easy to use

- Unequalled productivity - quality ratio

microB range

CNC belt grinding and satin-finishing machines

- MicroB: material removal by absolute dimension control of apply force of the controlled pad

- MicroB-CNC: control of material removal or absolute dimension through a numerical axis

- MicroB-S: Decorative finish "lengthwise satin finishing" or "straight graining"

microP

Automatic polishing, deburring & brushing machine with rotating table

- Ergonomic work station

- Workpieces loaded in concurrent time

- Simplified application of polishing compound controlled by MMI or by operator

BU200

Manual finishing machine

- High precision spindle with Schaublin type W20 collet

- Manually adjustable feeding speed

- Premier quality mechanical and electrical components

BU210

Manual finishing machine

- Manual or semi-automatic work modes

- High precision spindle with Schaublin type W20 collet

- Feeding speed adjustable manually or automatically with pre-programmed cycles

microC

Automatic brush carding machine

- Carding with no risk of injury to the operators in a dust-free environment

- Uniform and regular brush preparation

- Various carding tools available

MR360

Grinding machine

- Digital Z axis with linear motor force-controlled during machining, to avoid chipping

- With 3 linear axes and 1 rotary axis with manual adjustment

- 2 versions of tool spindle, 19'500 or 60'000 rpm

Precision Watchmaking by Recomatic: Polishing and Grinding in the Service of Time

At the heart of Swiss watchmaking excellence, Recomatic stands as an essential partner for the most demanding brands. Our expertise is rooted in a deep mastery of polishing and grinding techniques, ensuring unmatched quality and precision for every component.

Backed by a long tradition of innovation and modernized craftsmanship, our dedicated teams employ high-precision polishing processes to enhance surfaces, eliminate imperfections, and give watch parts a brilliant and exceptional finish. Whether cases, bracelets, or delicate internal components, our polishing expertise ensures impeccable aesthetics that meet the highest standards of luxury watchmaking.

At the same time, our grinding department plays a crucial role in achieving extremely tight dimensional tolerances, essential for the proper function and longevity of watch mechanisms. Using state-of-the-art equipment and meticulous know-how, we carry out grinding operations with micrometric precision, ensuring perfect component fit and optimal reliability.

At Recomatic, we understand that every detail matters in the world of watchmaking. That?s why we bring passion and expertise to our clients, offering tailored polishing and grinding solutions that meet the unique needs of each project. Trust Recomatic?s expertise to elevate your watch creations and ensure a level of quality that stands the test of time.